Let’s talk about film capacitor types, my friends. If you’ve ever been curious about how these tiny powerhouses work and why they’re essential in modern electronics, you’re in the right place. Capacitors are like the unsung heroes of the electrical world, quietly doing their job to make sure your gadgets function properly. But not all capacitors are created equal, and that’s where film capacitors come in. They’re a special breed with unique properties that make them perfect for specific applications.

Now, if you’re into electronics, engineering, or just plain curious about how things work, this article is going to be a game-changer for you. We’ll break down the different types of film capacitors, their uses, and why they matter. Think of it as a treasure hunt for knowledge, where every paragraph brings you closer to becoming a film capacitor expert.

So grab your favorite drink, sit back, and let’s dive into the world of film capacitor types. By the end of this, you’ll know more than most people out there—and maybe even impress your friends at your next dinner party. Let’s roll!

- Alicerosenbum Onlyfans

- Vegamovies 2025 18 Your Ultimate Guide To The Future Of Adult Entertainment

- Freemovies2021 Com

- Dotmovies Web Your Ultimate Destination For All Things Movies

- Bollyflix

What Are Film Capacitors Anyway?

Film capacitors are like the cool kids in the capacitor world. They’re made using a thin plastic film as the dielectric material, which gives them some serious advantages over other types. But what makes them so special? Let me break it down for you. Film capacitors are known for their reliability, stability, and ability to handle high voltages. They’re like the superheroes of the electronics industry, stepping in when other capacitors just can’t cut it.

One of the coolest things about film capacitors is their ability to maintain performance over time. Unlike some other capacitors that degrade quickly, film capacitors can last for years without losing their mojo. This makes them perfect for applications where longevity and reliability are key, like in power supplies, motor controls, and even renewable energy systems.

Why Should You Care About Film Capacitor Types?

Here’s the deal: not all film capacitors are the same. Depending on the application, you’ll need a specific type of film capacitor to get the job done right. Think of it like choosing the right tool for a job. You wouldn’t use a screwdriver to hammer a nail, right? Same goes for capacitors. Using the wrong type can lead to inefficiencies, failures, or even safety hazards.

- Unlock The Secrets Of Aagmaalin Your Ultimate Guide To The Platform Everyones Talking About

- Jackermans Mothers Warmth Chapter 3 Release Date Fan Frustration

- Dive Into Honeytoon Romance Adventure More

- Viralkandcom

- Httpsviralkandcom

Understanding the different types of film capacitors will help you make informed decisions when designing or troubleshooting electrical systems. Whether you’re an engineer, a hobbyist, or just someone who wants to know more about how things work, this knowledge is invaluable. So let’s get into the nitty-gritty of film capacitor types and see what makes each one unique.

Types of Film Capacitors: The Main Players

Alright, let’s get down to business. There are several types of film capacitors, each with its own strengths and weaknesses. Here’s a quick rundown of the main players:

- Polyester Film Capacitors (PET): These are the workhorses of the film capacitor world. They’re cheap, reliable, and can handle a wide range of voltages. Perfect for general-purpose applications.

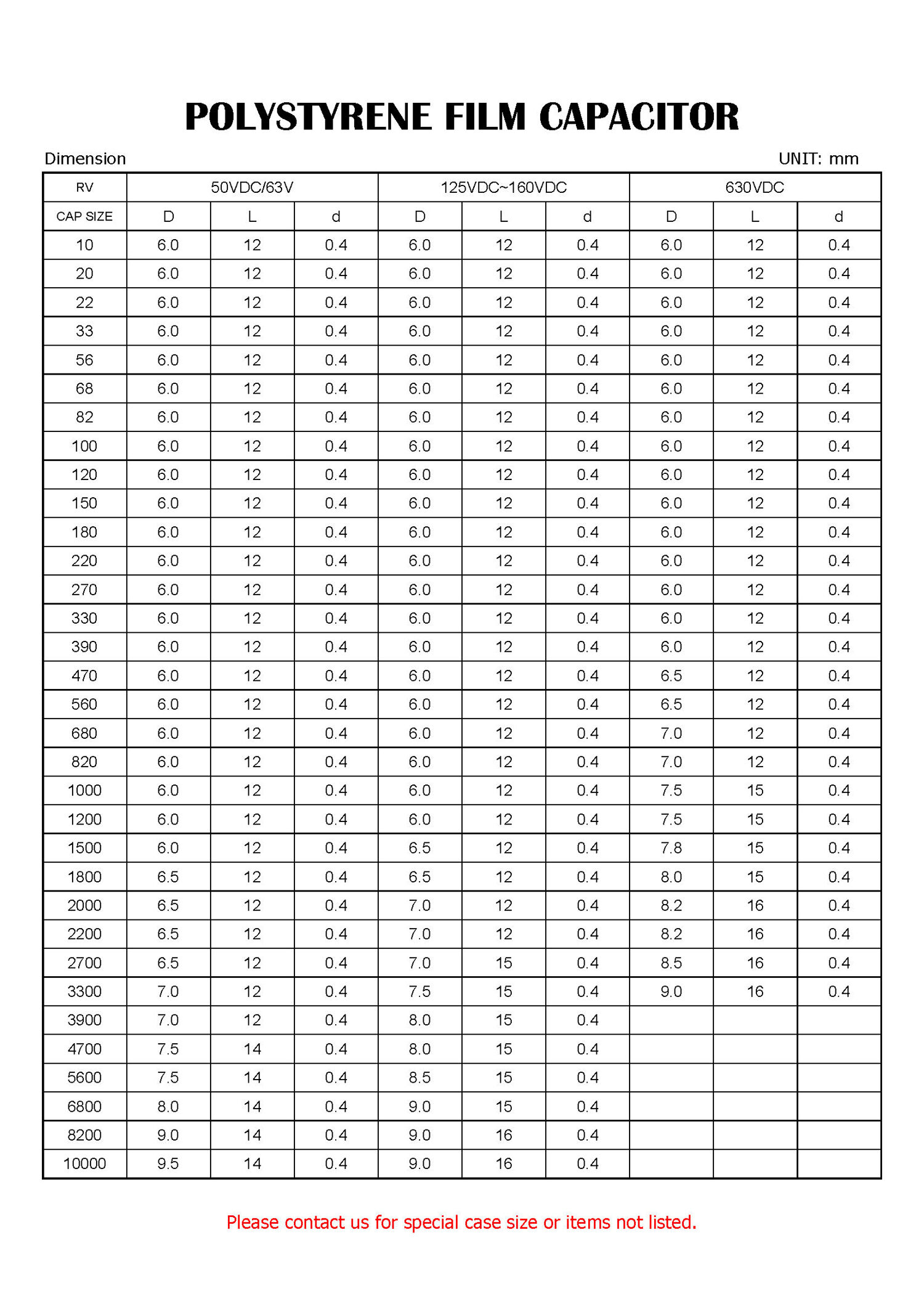

- Polystyrene Film Capacitors: Known for their high stability and low losses, these capacitors are ideal for precision applications like oscillators and filters.

- Polypropylene Film Capacitors (PP): These bad boys are the go-to choice for high-voltage and high-frequency applications. They offer excellent stability and low dielectric losses.

- Polyethylene Naphthalate (PEN) Film Capacitors: These capacitors are like the all-rounders of the film capacitor world. They offer a good balance of performance, cost, and temperature stability.

Each type has its own unique properties that make it suitable for specific applications. Understanding these differences will help you choose the right capacitor for your needs.

Applications of Film Capacitors

Now that we know the different types, let’s talk about where they’re used. Film capacitors are everywhere, from your smartphone to the wind turbines powering your home. Here are some of the most common applications:

- Power Supplies: Film capacitors are used to smooth out voltage fluctuations in power supplies, ensuring a steady flow of electricity to your devices.

- Motor Controls: In motor control systems, film capacitors help improve efficiency and reduce energy losses.

- Renewable Energy Systems: From solar panels to wind turbines, film capacitors play a crucial role in energy storage and conversion.

- Audio Equipment: High-quality film capacitors are used in audio systems to ensure clear and distortion-free sound.

As you can see, film capacitors are versatile and essential in a wide range of applications. Knowing which type to use for each application is key to getting the best performance out of your system.

Advantages of Film Capacitors

So why should you choose film capacitors over other types? Here are some of the key advantages:

- High Reliability: Film capacitors are known for their long lifespan and ability to maintain performance over time.

- Low Losses: They offer low dielectric losses, making them ideal for high-frequency applications.

- Temperature Stability: Film capacitors can operate effectively over a wide range of temperatures, making them suitable for harsh environments.

- Self-Healing Properties: Some film capacitors, like polypropylene, have self-healing properties that allow them to recover from minor faults.

These advantages make film capacitors a top choice for many engineers and designers. They offer a combination of performance, reliability, and versatility that’s hard to beat.

Disadvantages and Limitations

Of course, no technology is perfect. Film capacitors do have some limitations that you should be aware of:

- Cost: Some types of film capacitors, like polypropylene, can be more expensive than other capacitor types.

- Size: Film capacitors can be larger than other types, which might be a concern in space-constrained applications.

- Capacitance Range: Film capacitors typically have a limited capacitance range, which might not be suitable for all applications.

Despite these limitations, the advantages of film capacitors often outweigh the disadvantages, making them a popular choice in many applications.

How to Choose the Right Film Capacitor

Picking the right film capacitor can seem overwhelming, but it doesn’t have to be. Here are some factors to consider:

- Voltage Rating: Make sure the capacitor can handle the voltage requirements of your application.

- Capacitance Value: Choose a capacitor with the right capacitance value for your circuit.

- Temperature Range: Consider the operating temperature range of your application and choose a capacitor that can handle it.

- Frequency Response: If your application involves high frequencies, choose a capacitor with low dielectric losses.

By considering these factors, you can narrow down your options and choose the right film capacitor for your needs.

Top Manufacturers and Brands

When it comes to film capacitors, quality matters. Here are some of the top manufacturers and brands to look out for:

- Kemet: Known for their high-quality film capacitors and extensive product range.

- Vishay: Offers a wide range of film capacitors for various applications.

- TDK: A trusted name in the capacitor industry, offering reliable and innovative solutions.

- AVX: Provides a comprehensive selection of film capacitors for different industries.

These manufacturers are known for their commitment to quality and innovation, making them a safe choice for your film capacitor needs.

Future Trends in Film Capacitors

As technology continues to evolve, so does the world of film capacitors. Here are some trends to watch out for:

- Miniaturization: Film capacitors are getting smaller and more efficient, allowing for more compact designs.

- Improved Materials: New materials are being developed that offer better performance and reliability.

- Sustainability: There’s a growing focus on making capacitors more environmentally friendly, from using recyclable materials to reducing waste.

These trends are shaping the future of film capacitors and opening up new possibilities for innovation and growth.

Conclusion: Take Action, My Friends

There you have it, folks. Film capacitor types are more than just a technical detail—they’re a crucial part of modern electronics. Whether you’re designing a new product, troubleshooting an existing system, or just expanding your knowledge, understanding film capacitors is essential.

So what’s next? Leave a comment below and let me know what you think. Share this article with your friends and colleagues who might find it useful. And don’t forget to check out our other articles for more insights into the world of electronics. Together, we can keep the knowledge flowing and make the world a better place—one capacitor at a time. Cheers!

- Aditi Mistry Nipple Slip Details Reactions And Controversy Explained

- Unveiling Daniel Giersch His Life Controversies Explained

- Jamelizzzz Erome The Enigmatic Internet Star You Need To Know

- Movierulz Kannada 2024 Safe Alternatives Risks You Need To Know

- Httpsviralkandcom